Incredible as always. This could be the most comprehensive resto there's ever been on an s15. Can I ask what they do to prevent the rust in future?

To get the exact details of the process and product used, it would probably be better to ask them directly .

but as far as I understand :

- First the panels spot welds are drilled to expose the panel seams or to remove the panel completely.

- They grind(sand blast for the front panel) cut and reweld panel where necessary to remove all the rust .

- Once the rust is out of the panel, it gets rust converted to make sure everything is completely gone .

- The panel is then primed and welded back in place .

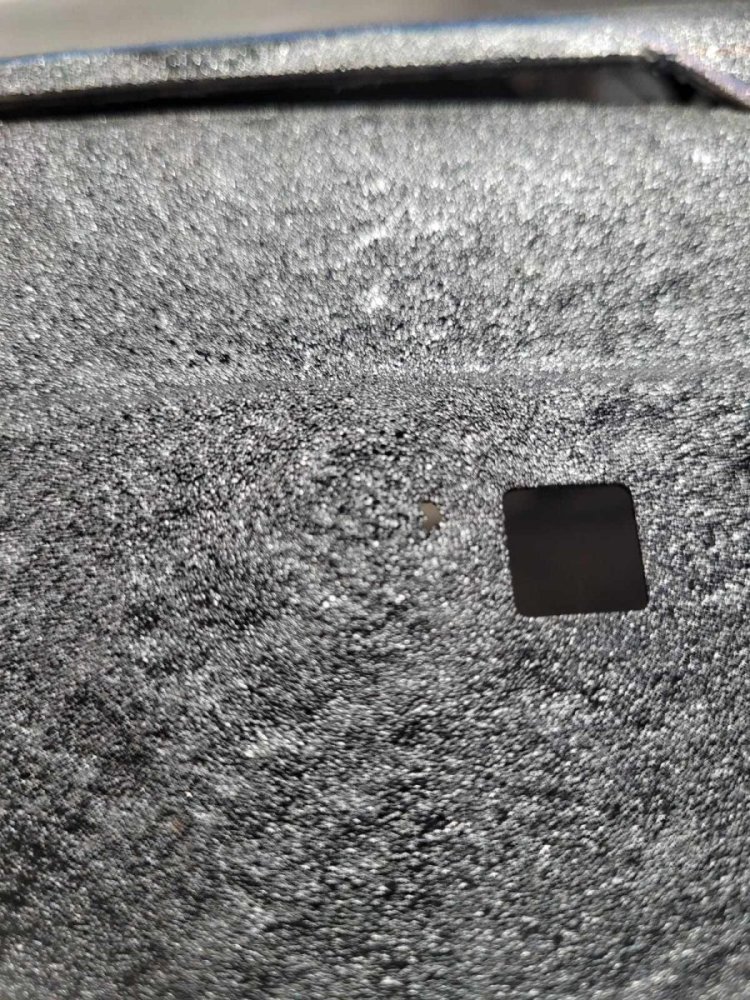

- Once all panels got cleaned and back on the car, the shell was pumped with an epoxy coating until it oozed out of every seams to make sure all the panels inner are covered and sealed .

- seam sealant is then applied and the shell sent for paint .

but as far as I understand :

- First the panels spot welds are drilled to expose the panel seams or to remove the panel completely.

- They grind(sand blast for the front panel) cut and reweld panel where necessary to remove all the rust .

- Once the rust is out of the panel, it gets rust converted to make sure everything is completely gone .

- The panel is then primed and welded back in place .

- Once all panels got cleaned and back on the car, the shell was pumped with an epoxy coating until it oozed out of every seams to make sure all the panels inner are covered and sealed .

- seam sealant is then applied and the shell sent for paint .

What do you do for a living?Plenty has happened in the last few month . The car goes to paint in August, the engine bay is getting the last few touches and sealer before .

View attachment 2565View attachment 2563

In the meantime I got the once in a lifetime opportunity to work in Japan for 2 years . One thing leading to another, I now own a chaser at Ebisu.

View attachment 2566View attachment 2567

View attachment 2568

To be fair I don’t know much about body kits but after a bit of googling the kit is probably a ito auto V1 kit .What do you do for a living?... And what wide arch kit does that chaser have, that's so clean!?

The car is slowly turning into a missile so the kit probably won’t last forever .

I work as a 3D modeler for Nissan design Europe in London . It’s pretty common for Japanese multinationals to offer the possibility for employees to transfer between different production sites . I couldn’t refuse when the offer came around!!

Do you know how long HTD guarantee their work for? Is the expectation after all this that it is basically impervious to rust now?

I haven’t ask if they guarantee their work .

I assume the shell will be good for a few years but keep in mind that I use my car all year round even in winter so rust will always come back . I believe this should still seal it much better than the factory paint .

I assume the shell will be good for a few years but keep in mind that I use my car all year round even in winter so rust will always come back . I believe this should still seal it much better than the factory paint .

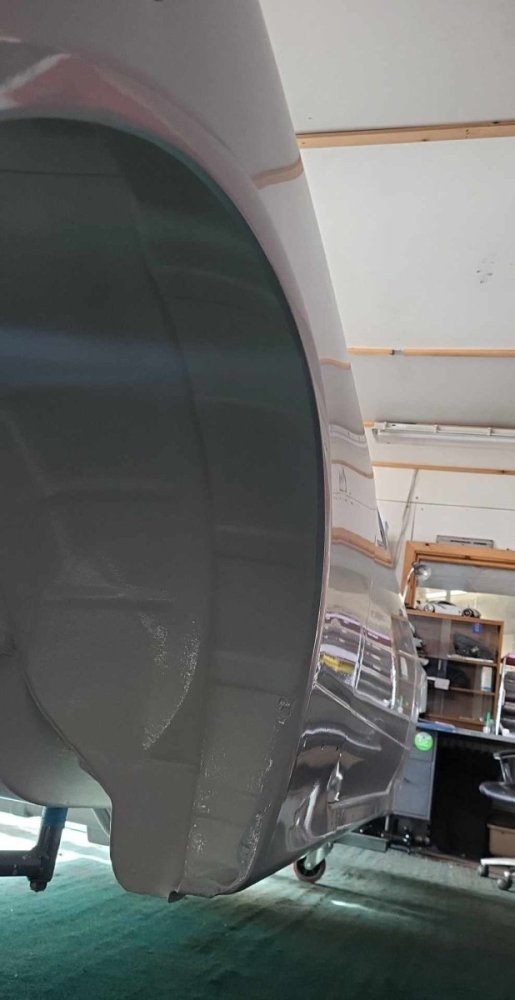

it's been a minute since the last update . The shell is back from the paint shop and back with HTDevelopments . The painter still has to come back to do a final cut once the paint has harden and the other panels are on the car .

The HTDevelopments workshop is pretty busy this year and I will still be living out of the country until 2026 so the reassembly has been scheduled to start in May .

It's pretty much the final stretch now . I can't wait to see all the nice cleaned parts going back on the shell!!

The HTDevelopments workshop is pretty busy this year and I will still be living out of the country until 2026 so the reassembly has been scheduled to start in May .

It's pretty much the final stretch now . I can't wait to see all the nice cleaned parts going back on the shell!!

About Us

This owners club has been made in the benefit of owners of the Nissan Silvia chassis, allowing them to socially integrate and share their knowledge and advice.

We also intend to create events and social activities for members to take part in to help members meet and get to know each other.

We also intend to create events and social activities for members to take part in to help members meet and get to know each other.

Online statistics

- Members online

- 0

- Guests online

- 523

- Total visitors

- 523

Totals may include hidden visitors.