So, brought this in 2008 from a guy in Auckland, NZ. being 18 years old and not knowing much/the finer points brought the car with some issues, those were fixed and on our way, then alot of parts where robbed off her one night.

All of the above was stolen, Car sat there for a while, insurance didnt want to know anything about it, so, she sat there and saved up for more parts.

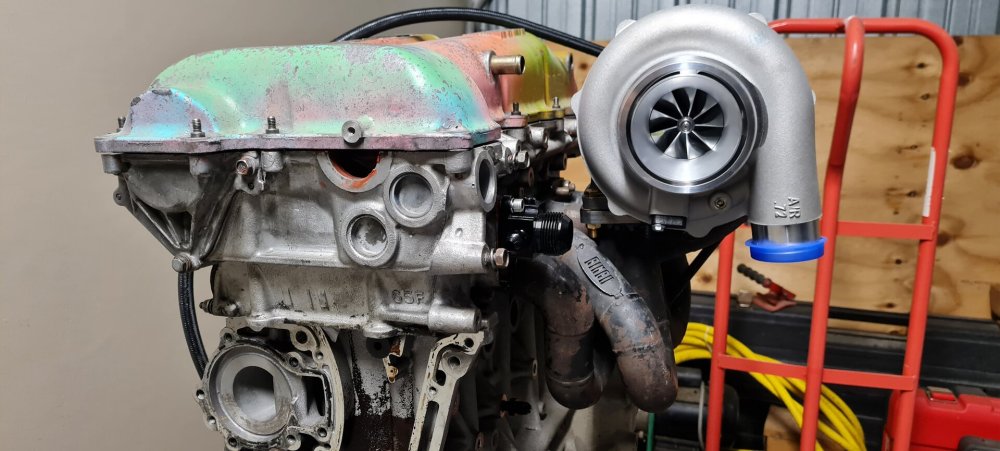

Come 2011-2012, after the car was sitting gathering dust, i decided to put more time/money into her. Found that the previous only had snapped the last exhaust stud off in the head and decided he would drill in in place and made a mess. We pulled the engine out, found it had a standard clutch(not a nismo clutch) and put it away in dry storage, brought a replacement long block for 2k and set about stripping the factory parts off and upgrading small parts on it.

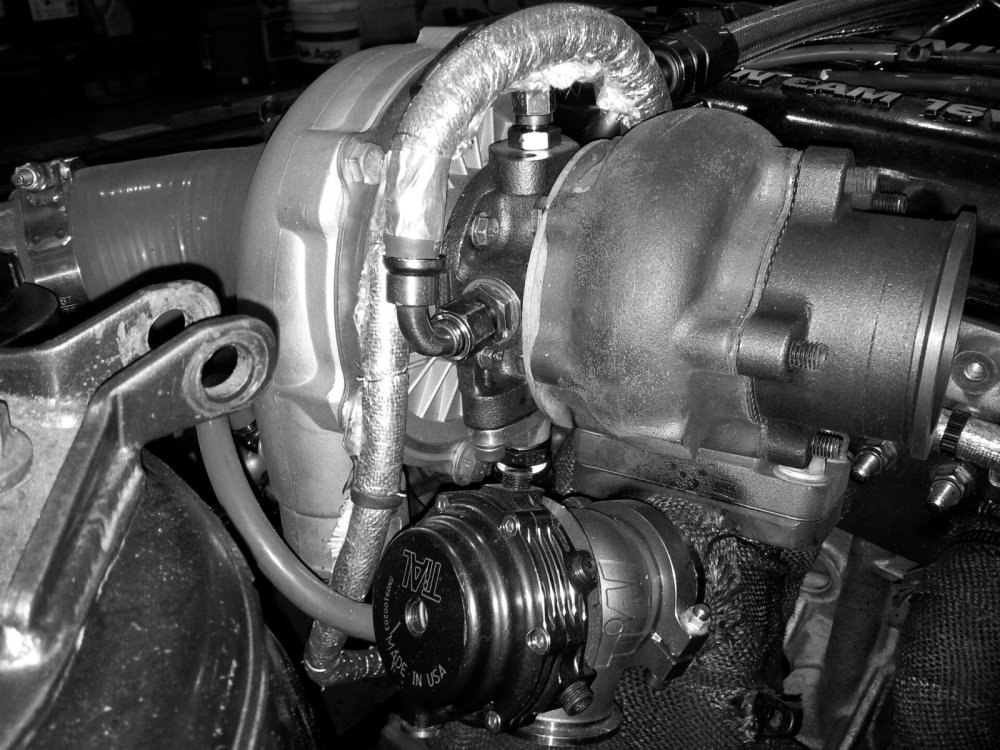

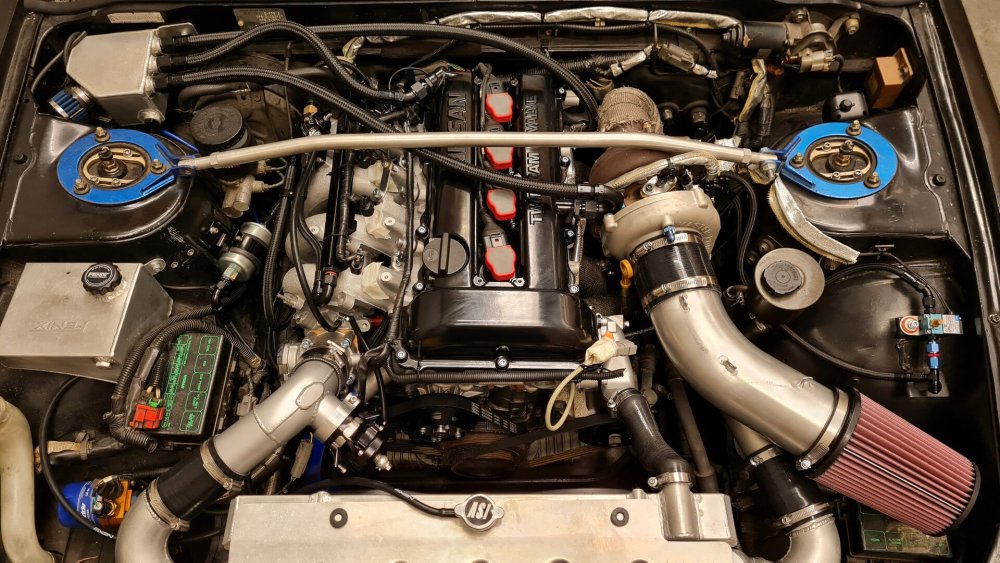

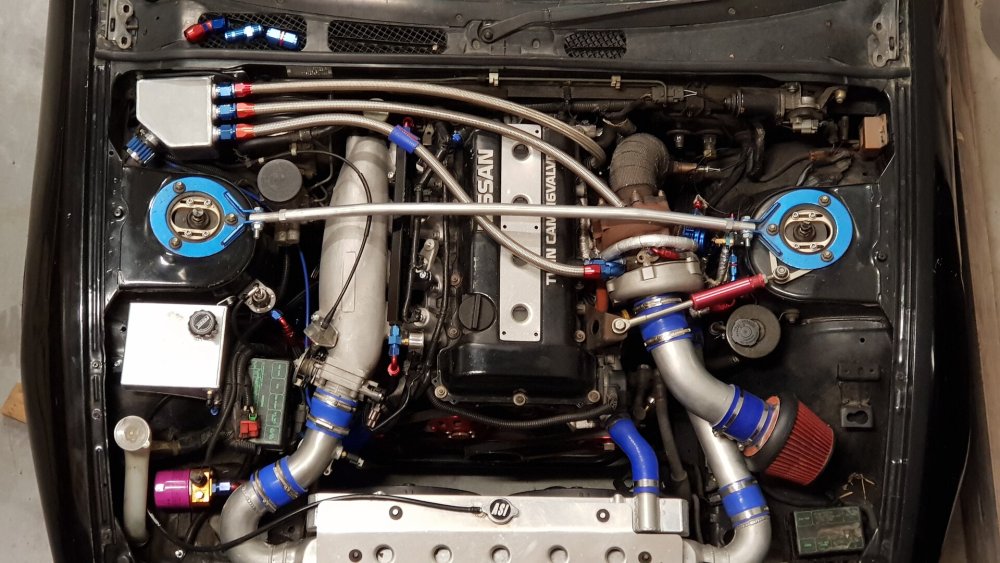

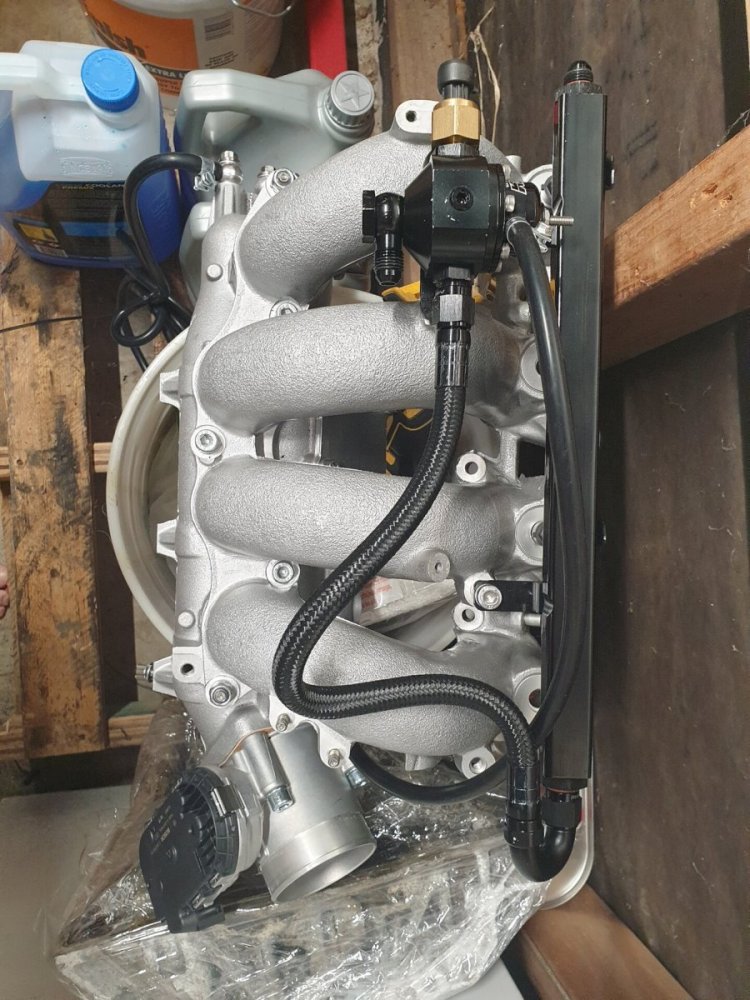

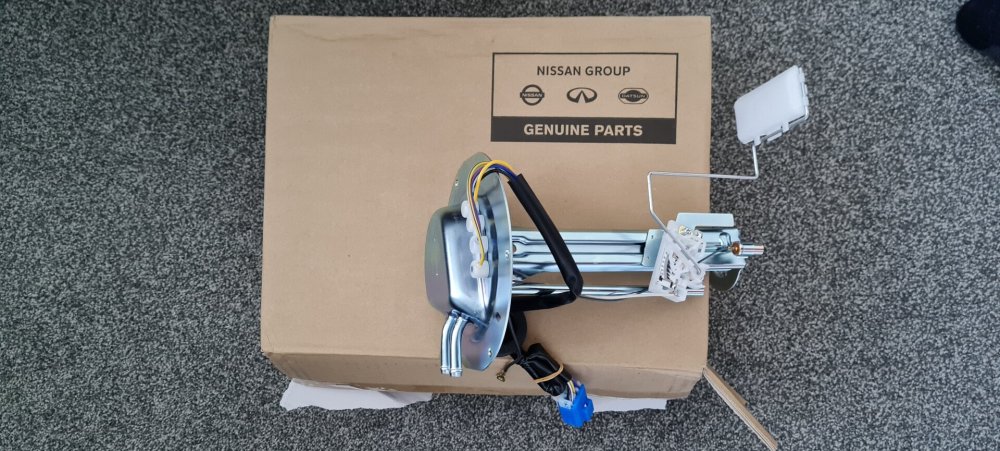

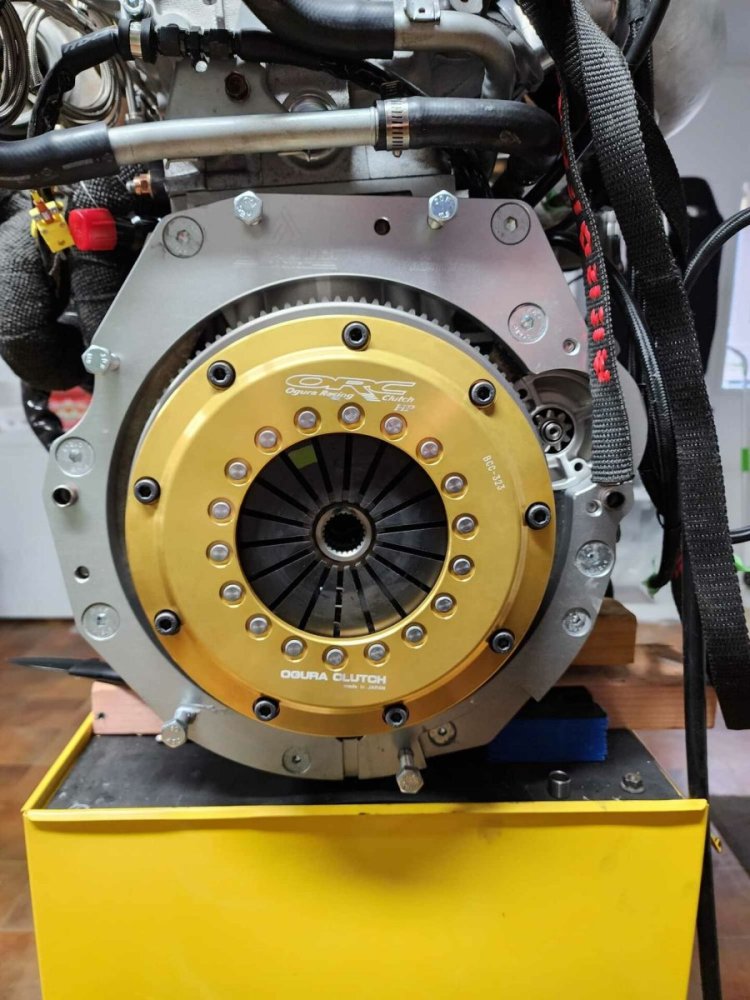

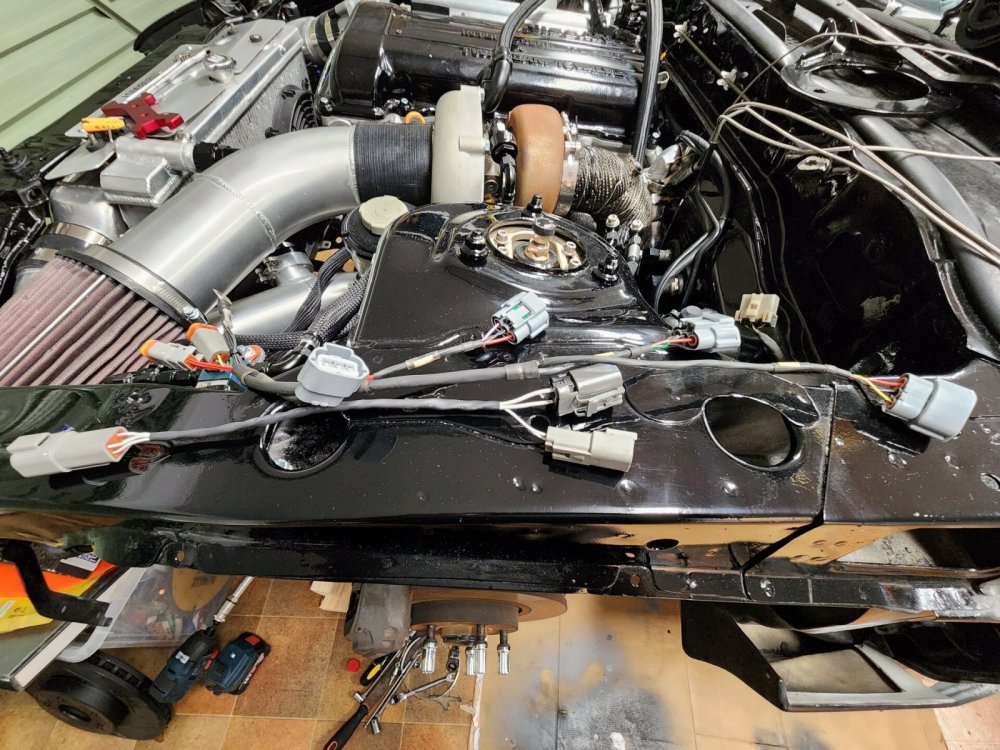

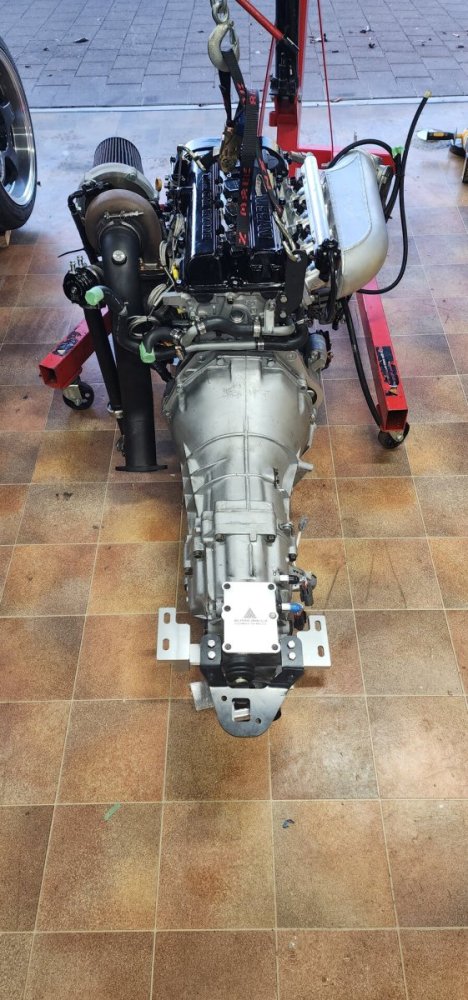

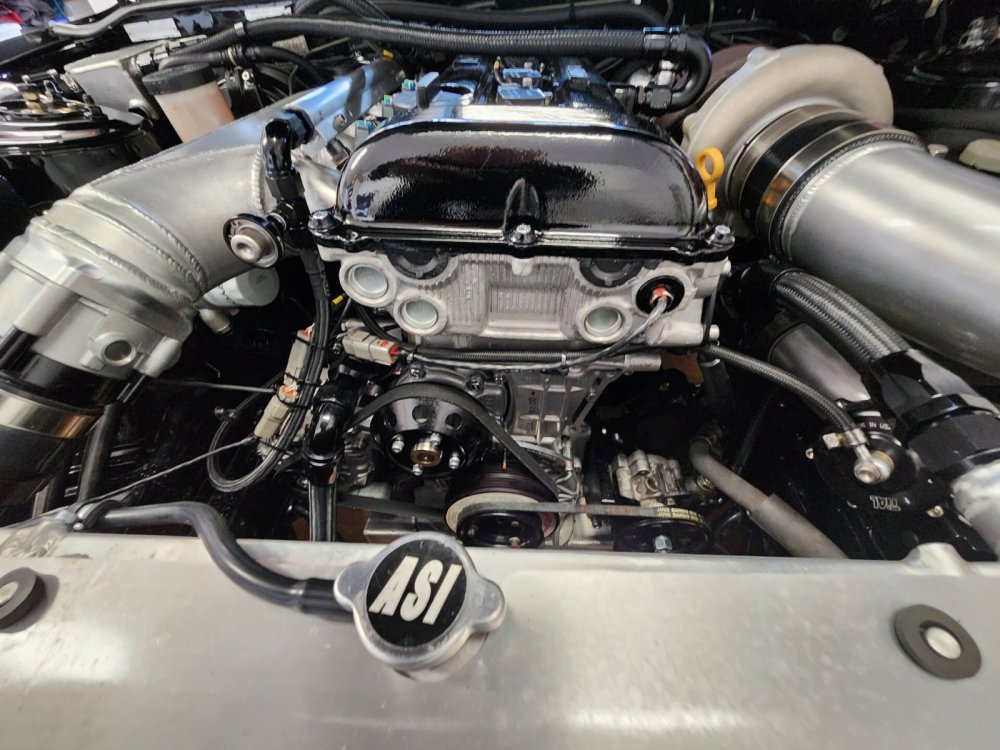

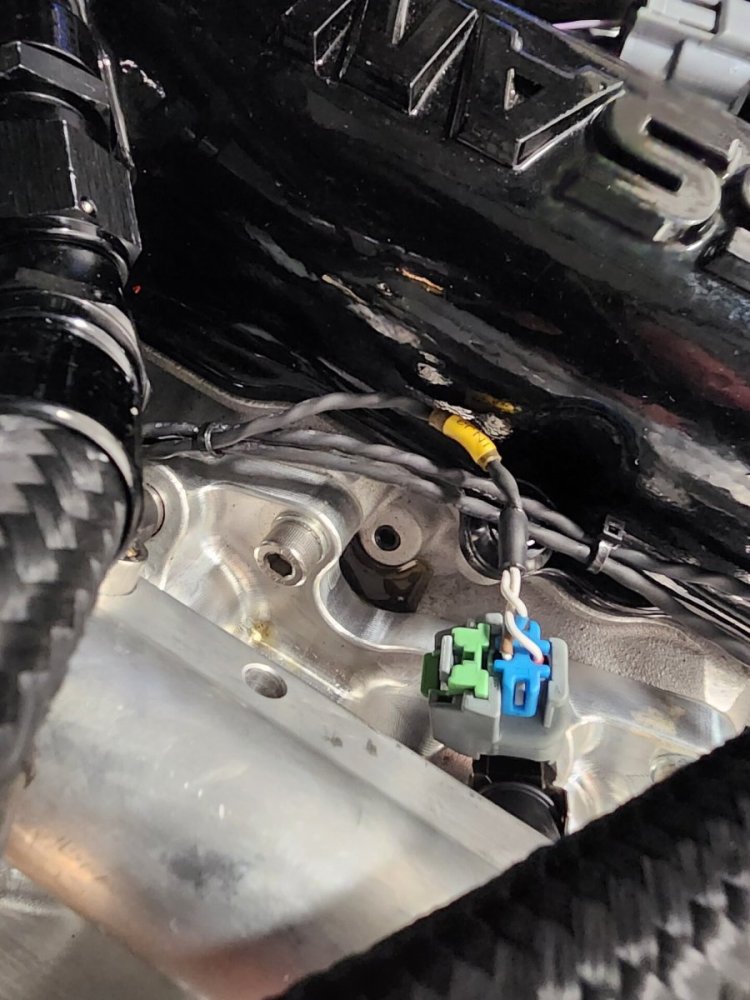

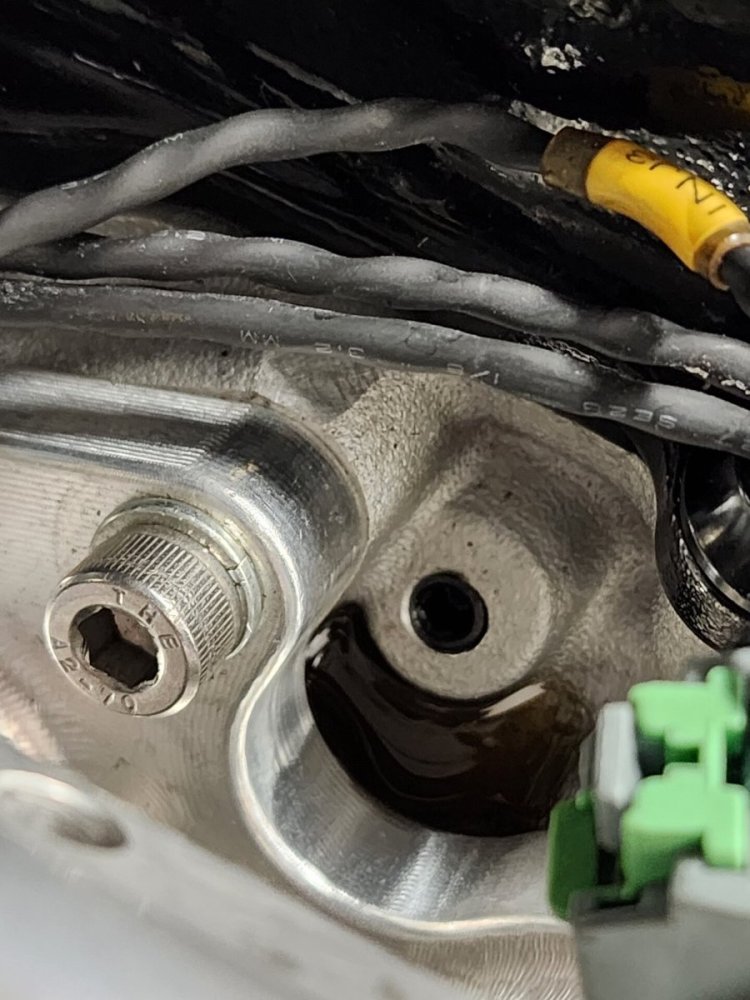

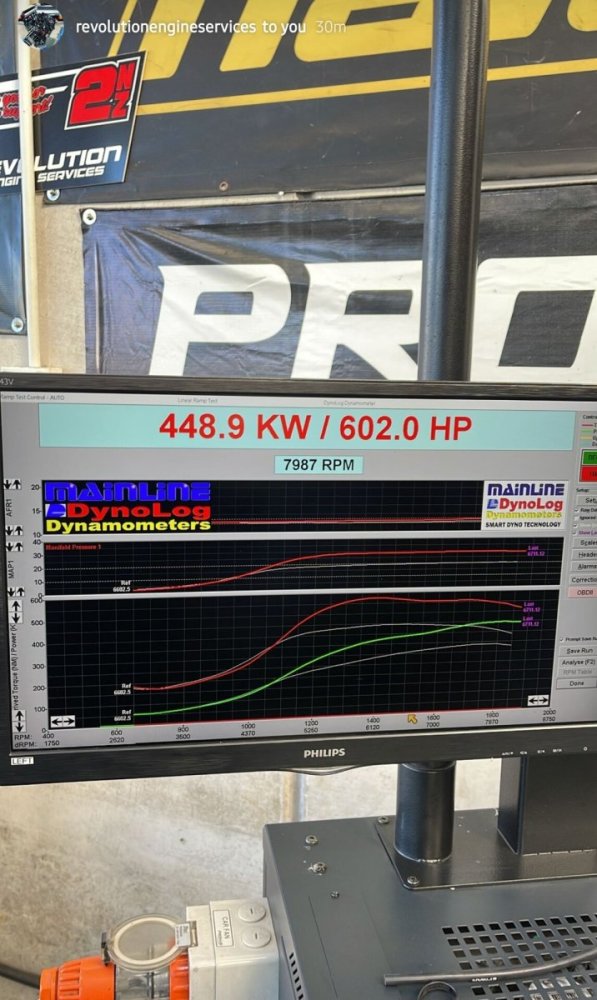

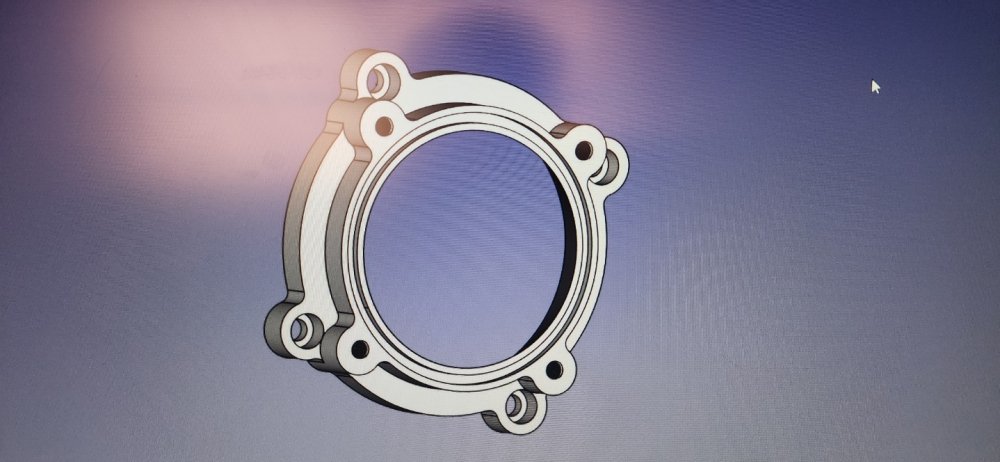

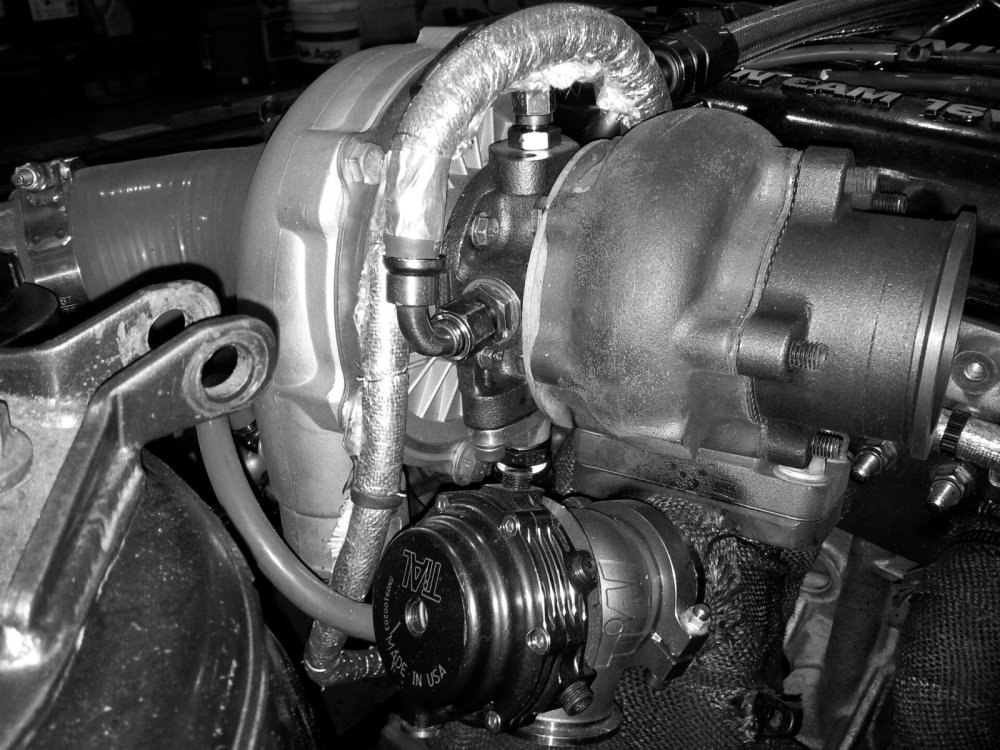

Decided to replace the factory sump for a larger cast ali chinese copy, Sinco customs top mount manifold, DSR430 turbo, TiAL 38mm vband wastegate, Xtreme HD clutch, 52mm ali radiator, fixced back bucket seats, harnesses, walbro 500hp intank pump, off to fabrication.

All of the above was stolen, Car sat there for a while, insurance didnt want to know anything about it, so, she sat there and saved up for more parts.

Come 2011-2012, after the car was sitting gathering dust, i decided to put more time/money into her. Found that the previous only had snapped the last exhaust stud off in the head and decided he would drill in in place and made a mess. We pulled the engine out, found it had a standard clutch(not a nismo clutch) and put it away in dry storage, brought a replacement long block for 2k and set about stripping the factory parts off and upgrading small parts on it.

Decided to replace the factory sump for a larger cast ali chinese copy, Sinco customs top mount manifold, DSR430 turbo, TiAL 38mm vband wastegate, Xtreme HD clutch, 52mm ali radiator, fixced back bucket seats, harnesses, walbro 500hp intank pump, off to fabrication.